Textile Printing Grade CMC

Carboxymethyl Cellulose for Textile Printing Thickener

CMC can form a firm and strong sheet with a certain level of softness and wear resistance, and stick well to the fiber surface. In addition, it provides the chaine with sufficient elongation characteristics, increasing the textile strength during the manufacturing process, enhancing production efficiency, and taking thickening effect as well. It can be widely applied in the textile industry, such as warp sizing, textile printing, and fabric finishing, etc.

Application in Textile Printing

In the search for sodium alginate substitutes, synthetic pastes, modified starches, and guar gum have become the focus of related research at home and abroad, while sodium carboxymethyl cellulose (CMC) has received little attention.

An important factor is its DS (degree of substitution). The DS refers to the average number of sodium methyl carboxylate groups attached to each cellulose unit. When salt is added to a CMC solution, it will hardly affect the viscosity (not even after a long storage time) while a CMC dissolved in an aqueous electrolyte solvent may show a much lower viscosity than expected. High DS CMC is less sensitive towards electrolytes than medium or low substituted grades. The reason for this is that, although some of the sodium ions of the CMC will be replaced, there is still enough unpreturbed Na-CMC to maintain the viscosity.

The regular CMC products, degree of substitution is generally 0.6 ~ 0.9. There are still a large number of active hydroxyl groups in the molecule, it is easy to react with reactive dyes, and reactive dye printing cannot be used. Therefore, the CMC with low DS can be ignored as a reactive dye printing paste.

When the DS is high, like 1.3~2.3, carboxymethyl cellulose can be used as the printing paste of reactive dyes. Experiments have proven that the CMC with a ultra high DS >2.0 can 100% replace sodium alginate in reactive dye printing.

CMC with ultra high DS can be used as a thickener in various textile printing color paste, and it has excellent anti-acid and anti-salt (electrolyte endurance) properties. The viscosity is stable after making up the thickener and printing color paste, and it can fully replace high quality sodium alginate.

Advantages:

Fuxin™ brand textile printing grade CMC has high color yield, fine paste, good shear thinning performance and chemical stability, and good printing effect. It shows good functional effects and cost-effective advantages when proccessing:

- High color yield (10%-20% higher than sodium alginate), which can directly reduce dye consumption costs.

- Good chemical stability, good compatibility with printing and dyeing auxiliaries and dyes, not easy to spoil during storage, no need to add preservatives.

- Chemical stability of color paste is much better than sodium alginate, especially in summer.

- Good water retention and high structural viscosity. It has good shear thinning performance under the action of shear stress, excellent screen penetration performance, uniform printing block surface, high outline definition, and smooth lines.

- It has good solubility and can be quickly dissolved in cold water under stirring conditions, no gum clump, save beating time.

- Easy to wash off and good hand feeling .

- The cost-effectiveness advantage is obvious. Compared with sodium alginate, it can directly reduce the use cost and improve economic benefits.

Performance of Ultra High DS CMC

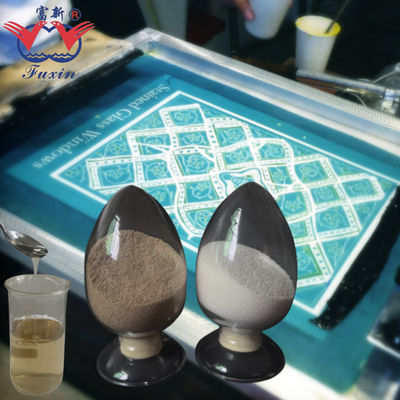

Left pic:Dyed color granular CMC 2% solution Right pic: The left is standard product made in Italy. The middle and right are Fuxin different types of CMC.

Specification

| TYPE |

Degree of Substitution (DS) |

Viscosity

(Brookfield,1%soln.,20℃)

|

pH |

Moisture |

Particle Size |

| 10H |

1 |

2500-3000cps |

6.5-8.5 |

≤15% |

20-70 mesh |

| 13H |

1.3 |

1500-2500cps |

| 15H |

1.5 |

1000-2000cps |

| 18H |

1.8 |

800-1600cps |

| Y002 |

2 |

800-1500cps |

| Y230 |

2.3 |

600-1000cps |

*Kindly contact us for specification and information about any specific grade of CMC other than mentioned in the above table.

Powder or granular available, we recomed customer to purchase the brown granle type CMC to sell as sodium alginate for higher profit.

Technique Process

▲Dissolve the dyes and add into the paste, make the color paste with thickener→▲Printing→▲Drying (100 ℃)→▲Baking or steaming→▲Washing→▲Soaping→▲Rinsing→▲Post treatment procedure.

Dissolution Methods and Proportion:

How to make the paste?

1. The ratio depends on DS level, low DS product should mix with pure sodium alginate to reach a better performance, while ultra high DS product can 100% replace SA.

2. Proportion: same as sodium alginate original paste preparing. Firstly add 65% water, stir the water while adding the product evenly and slowly, then speed up the stirrer for 20-25 minutes. And then add the remaining 35% water, stir for another 20-30 minutes. Leave for 15 minutes.

How to make sure the paste dissove completely?

1. Powder and water completely fuse, not exist solid-liquid separation phenomenon.

2. Paste is dissolved evenly, the surface is smooth, no granular objects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!