Product Description:

"Fuxin™ Brand Reactive Printing Thickener"

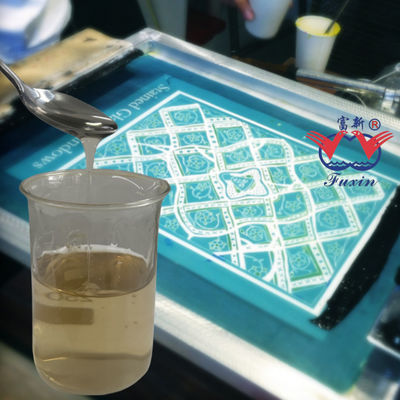

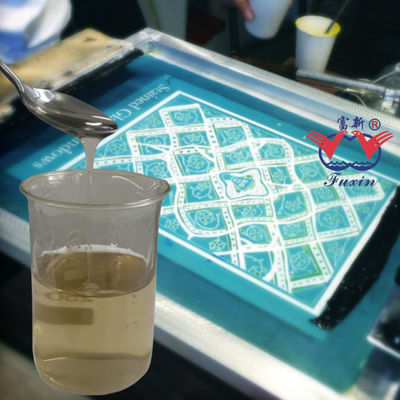

Experience the revolution in textile printing with our exclusive Fuxin™ brand Reactive Printing Thickener. Crafted with precision, this innovative thickener, based on Carboxymethyl Cellulose (CMC), brings your textile designs to life in vibrant color. Its unique properties enable it to create firm and robust sheets with a touch of softness and wear resistance that's second to none. Fuxin™ Reactive Printing Thickener adheres seamlessly to textile fibers, providing enhanced strength during the manufacturing process, boosting production efficiency, and delivering exceptional thickening effects.

With broad applications across the textile industry, including warp sizing, textile printing, and fabric finishing, Fuxin™ brand CMC is your trusted companion for achieving the highest quality in textile creations. It offers unparalleled performance, setting new standards in color retention, print quality, and eco-friendliness. Choose Fuxin™ for textile printing that stands out.

Reactive Printing Thickener is a chemical additive, specially created for the textile industry. It has been developed to boost the thickness and flow of printing pastes during the printing process. This results in better accuracy and print definition, which is of course important for achieving quality designs.

It accomplishes this in a few ways. Firstly, it increases the viscosity of the printing paste, and in turn, improves the control and stability that allows for more precise printing. Furthermore, it ensures that the designs are outlined with sharper precision.

Features:

Sodium carboxymethyl cellulose aqueous solution has a number of advantages for use in production and weaving processes. It is clear and transparent, homogenous and highly stable, and has no change due to mechanical force, temperature, or bacteria. In addition, the yarn processed with it is easily dry and glossy, with a soft hand feel and no yellowing or mildewing. Desizing is also very simple and efficient, requiring no chemical treatment or extra desizing agents. This is more convenient compared to using starch, which requires a full set of precise machinery and instruments, and which complicates the production process and increases maintenance costs.

The viscidity and film-forming property of the solution also provide benefits. It forms a smooth, wear-resistant and flexible film on warp surfaces, which can handle the absolute strength, relative activity and friction of the weaving machine, creating favorable conditions for weaving high-grade fabrics and accomplishing faster production cycles. It provides a cost-effective replacement for starch, improving sanitary conditions of the workshop and making maintenance of mechanical equipment more simple and efficient.

Applications:

Textile Printing: Reactive Printing Thickener is extensively used in textile printing, particularly for reactive dye-based printing methods. It is employed to thicken the printing paste, allowing for precise and controlled application of dyes onto fabrics. The thickener enhances the viscosity and rheological properties of the paste, ensuring sharp and well-defined printed designs.

Fabric Decoration: Reactive Printing Thickener plays a crucial role in fabric decoration by enabling the creation of vibrant and intricate patterns. It facilitates the bonding of reactive dyes with fabric fibers, resulting in excellent color fastness and resistance to fading. This makes it suitable for a wide range of fabric types, including cotton, rayon, silk, and blends.

Apparel Manufacturing: Reactive Printing Thickener is widely used in the production of printed textiles for apparel manufacturing. It allows for the creation of unique and visually appealing designs on garments, such as t-shirts, dresses, and scarves. The thickener ensures consistent and uniform printing results, enhancing the overall quality and aesthetic appeal of the finished products.

Support and Services:

- Technical Support: Reactive Printing Thickener provides technical support to customers for all its products. We provide detailed product information, troubleshooting guides, and assistance with installation and use. Customers can contact us by phone or email for any questions or issues.

- Services: Reactive Printing Thickener offers a variety of services to ensure the best performance of our products. We provide on-site maintenance, repair, and installation services. We also offer training and consultation services to help customers make the most of their products.

Packing and Shipping:

Reactive Printing Thickener

Packaging and Shipping:

- Reactive Printing Thickener is packaged in 25 kg bags.

- The bags are placed on pallets and shrink-wrapped.

- The pallets are then loaded into trucks and shipped.

- If needed, additional packaging such as protective wrapping or cushioning material is used to protect the product.

- The trucks are monitored for the duration of the shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!