Product Description:

Textile Printing Paste

Textile Printing Paste is a special mixture created and used in the textile industry. It serves to produce stylish designs with vivid colors on fabric. To achieve desired results, it usually contains a combination of dyes, pigments, thickeners, binders, and other additives.

The purpose of Textile Printing Paste is to transfer and deposit colors onto fabric with accuracy and evenness. It also provides necessary viscoelastic properties to help it stay in place during the printing process, preserving the pattern and design in the process.

Thickeners, such as pigment printing thickeners or reactive printing thickeners, are part of the paste too. They are added to help control the viscosity and improve the printing properties, which further involves preventing any color bleeding and ensuring sharp, high-definition patterns and designs.

Features:

Sodium carboxymethyl cellulose aqueous solution is a clear, transparent, homogeneous solution with favorable stability. It is not affected by mechanical force, temperature or bacteria, which makes it easy to use in production. This solution has a viscosity and film-forming property that forms a smooth, wear-resistant, and flexible film on the surface of warp. The yarn processed with it is easily dry and glossy with a soft hand feel. Since it doesn't get yellowing or mildewed, it dramatically reduces substandard goods with defective spots or greasy dirt, and avoids damages by worms or rats.

Using cellulose gum instead of starch can greatly simplify the requirements, improve the sanitary condition of the workshop, and make the maintenance of mechanical equipment more convenient. This not only helps to provide favorable conditions for weaving more exquisite high grade fabric and high-speed production, but also enhances the production capacity of the weaving machine.

Performance of Ultra High DS CMC

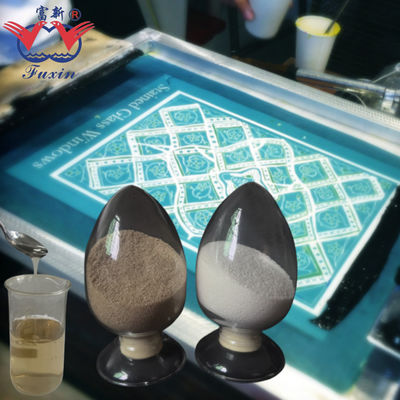

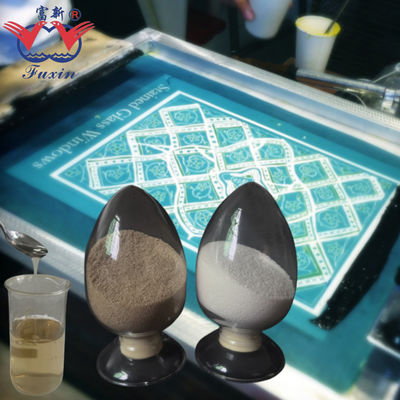

Left pic:Dyed color granular CMC 2% solution Right pic: The left is standard product made in Italy. The middle and right are Fuxin different types of CMC.

Specification

| TYPE |

Degree of Substitution (DS) |

Viscosity

(Brookfield,1%soln.,20℃)

|

pH |

Moisture |

Particle Size |

| 10H |

1 |

2500-3000cps |

6.5-8.5 |

≤15% |

20-70 mesh |

| 13H |

1.3 |

1500-2500cps |

| 15H |

1.5 |

1000-2000cps |

| 18H |

1.8 |

800-1600cps |

| Y002 |

2 |

800-1500cps |

| Y230 |

2.3 |

600-1000cps |

*Kindly contact us for specification and information about any specific grade of CMC other than mentioned in the above table.

Powder or granular available, we recomed customer to purchase the brown granle type CMC to sell as sodium alginate for higher profit.

Technique Process

▲Dissolve the dyes and add into the paste, make the color paste with thickener→▲Printing→▲Drying (100 ℃)→▲Baking or steaming→▲Washing→▲Soaping→▲Rinsing→▲Post treatment procedure.

Dissolution Methods and Proportion:

How to make the paste?

1. The ratio depends on DS level, low DS product should mix with pure sodium alginate to reach a better performance, while ultra high DS product can 100% replace SA.

2. Proportion: same as sodium alginate original paste preparing. Firstly add 65% water, stir the water while adding the product evenly and slowly, then speed up the stirrer for 20-25 minutes. And then add the remaining 35% water, stir for another 20-30 minutes. Leave for 15 minutes.

How to make sure the paste dissove completely?

1. Powder and water completely fuse, not exist solid-liquid separation phenomenon.

2. Paste is dissolved evenly, the surface is smooth, no granular objects.

Technical Parameters:

| Parameter |

Value |

| Model NO. |

Textile Grade |

| Sieving Limits (80 Mesh): |

Above 98% |

| Texture: |

Smooth |

| Viscosity: |

1.8% ≥15000cps |

| HS Code: |

3912310000 |

| Product Name: |

Textile Printing Paste |

| D.S.: |

Above 0.9 |

| CAS No.: |

9004-32-4 |

| pH Value: |

6.5-8.5 |

| Classification: |

Chemical Auxiliary Agent |

| Keywords: |

Pigment Paste for Textile Printing, Pigment Printing Thickener, Synthetic Thickener for Textile Printing |

Applications:

Apparel Manufacturing: Textile Printing Paste is extensively used in apparel manufacturing for adding decorative patterns and designs to garments. It allows for the creation of unique and visually appealing prints on various types of fabrics, including cotton, silk, polyester, and blends. The paste is applied through techniques such as screen printing, roller printing, or digital printing, enhancing the aesthetic appeal and marketability of the garments.

Home Textiles: Textile Printing Paste finds application in the production of home textile products, including bed linens, curtains, upholstery fabrics, and tablecloths. It enables the printing of intricate and decorative patterns on these textiles, enhancing their visual appeal and adding a touch of personalization to home decor.

Promotional Products: Textile Printing Paste is used for creating custom-designed promotional products, such as bags, caps, and t-shirts. It allows for the printing of logos, slogans, and graphics, enabling effective branding and marketing. The paste ensures accurate and durable prints on these promotional items, contributing to their overall visual impact and brand recognition.

Support and Services:

Technical support and services for Textile Printing Paste include:

- 24/7 customer service to answer any questions about Textile Printing Paste

- Unlimited access to a team of experts and technicians for troubleshooting and technical support

- Regular software updates and maintenance to ensure the latest features are available

- On-site installation and configuration to ensure optimal performance

- Training and workshops for users to get the most out of Textile Printing Paste

Packing and Shipping:

Textile Printing Paste will be packaged in air-tight containers and sealed for shipping. The containers will be placed in sturdy corrugated boxes with adequate cushioning materials. The boxes will be clearly labeled with the product name, logo, and other relevant information.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!